AWARD WINNING “Fast-Fire” Burner Technology! SOIL-THERM has been awarded the prestigious 2018 Technology Award from the Environmental Business Journal in March 2019! We appreciate the judges view of our latest direct fire combustion technology for the complete removal of Cannabis vapors and VOC’s during extraction operations. Local communities no longer have to worry about possible explosions and fires when processing Butanes and Propane for liquid extraction processing. SOIL-THERM destroys the explosive vapors safely and permanently.

SOIL-THERM “Direct Fire” Technology. We wish to thank the many customers and friends that came by to visit us at the TCEQ show in Austin, TX on May 15- 16. The response to our latest “Direct Fire” combustion technology for Tank Degassing and Enclosed Flare applications was terrific. We are looking forward to getting more systems out to refineries in the near future!

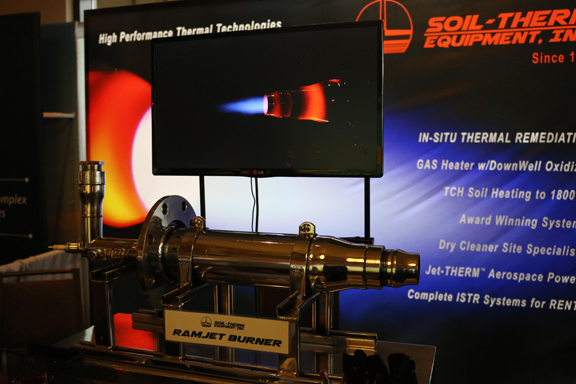

CVOC Oxidizer Technology Breakthrough! SOIL-THERM Jet-THERM burners have been modified in order to provide for the injection of high pressure air and fuel gas into the burner flame zone. This new patent pending process enables extreme turbulence and mixing with the CVOCs in the burner’s 3500°F flame zone where the Chlorinated compounds’ molecular structure is EXPLODED into HCl, CO2, and Water in milliseconds. More information to be provided at the Battelle Chlorinated Conference on April 8 – 12, 2018 in Palm Springs! See us at Booth #408.

CVOC Oxidizer Technology Breakthrough! SOIL-THERM Jet-THERM burners have been modified in order to provide for the injection of high pressure air and fuel gas into the burner flame zone. This new patent pending process enables extreme turbulence and mixing with the CVOCs in the burner’s 3500°F flame zone where the Chlorinated compounds’ molecular structure is EXPLODED into HCl, CO2, and Water in milliseconds. More information to be provided at the Battelle Chlorinated Conference on April 8 – 12, 2018 in Palm Springs! See us at Booth #408.

May 15-16, 2018. SOIL-THERM is attending the Austin TCEQ environmental show! Demonstrating our latest emissions control TANK DEGASSING oxidizer systems for our customers and visitors. We look forward to seeing all of you there at BOOTH #127!

April, 2018. SOIL-THERM will be presenting our latest ISTR Downwell heating technologies at the Battelle Chlorinated Conference in Palm Springs, CA. Since the last conference, SOIL-THERM has demonstrated our high temperature ISTR heating technology at several sites with excellent success. See us at Booth #408 for a miniature CVOC burner on display!

January, 2018.. SOIL-THERM Portable Blower Systems have been developed and are now being offered to our customers requiring remediation at Dry Cleaner Sites and very space restricted locations. These systems are small, mobile, and powerful SVE/DPE systems complete with water knockout, SVE blower, VFD for flow and vacuum control, touchscreen (upgrade), wheels, and a width of only 30″ to get through doors with easy 230V, 1-phase plug-in. Internet operation and monitoring ready. Video

November, 2017. SOIL-THERM has released its SMALLEST and MOST POWERFUL portable thermal remediation system ever! The SOIL-THERM NanoTHERM RS and NanoTHERM XL systems offer our latest burner advancements in small size and superior power. Field testing has proven >99+% D.E., smallest (30″ x 48″ skid) 250 scfm complete SVE oxidizer on the market and even has vacuum side and pressure side GAC hookups.

Fits anywhere, operates on 230V, single-phase plug-in, and quick connects to a 20 – 100 gallon propane tank for the fastest install times ever. Fuel Operating Costs: at 5% LEL, operation costs are as low as $0.50 per hour using propane. The NanoTHERM RS system is perfect for all types of pilot testing and fast response remediation needs! Or for those projects where you’re sick of waiting for the gas company to install your natural gas line with outrageous charges & lead times. These systems are designed to save you and your client money.

NanoTHERM RS: Easily load up your new NanoTHERM and roll it off the back of your truck, plug-in to a local “washing machine” type electrical 1-phase plug, and quick connect to a standard 100 gallon propane tank. SOIL-THERM can even provide you with a winch and ramp kit with your system. NO ridiculous waits and high fees or delays for your pilot testing or fixed site projects. And propane is as low as a $1 a gallon, which makes these systems even more convenient. We are pricing these systems competitively to lower your project costs!

JULY, 2015. SOIL-THERM’s Mark Sujata was interviewed by the Environmental Business Journal (EBJ) for their Remediation 2015 issue to provide our perspective on current and future trends in the Remediation market. SOIL-THERM discusses its latest advanced aerospace combustion projects and markets!

SoilTherm-InterviewEBJ-July2015

MARCH, 2015. SOIL-THERM’s presented our newest technology and display at the RemTEC Summit in Westminster, Colorado, from March 2-4th. SOIL-THERM introduced our high performance Ramjet Burner GAS-FIRED technology for DownWell heating and In-Situ Thermal Remediation (ISTR) after recent field studies demonstrated phenomenal heating and cleanup capabilities using a complete soil heating network system built by SOIL-THERM.

March 2015. SOIL-THERM received the prestigious Environmental Business Journal Award for Technology Merit: Remediation at the EBI Summit on March 11, 2015, San Diego, CA. The award was for (1) the Downwell Burner Technology and our DWR-1 Burner, (2) Heat Recovery during ISTR operation using a custom designed heat exchanger to recover well gas exhaust heat in order to preheat the DWR-1 burner operation, and (3) DownWell destruction of CVOC’s using a specially designed chlorinated oxidizer that fit within an 8″ well casing and could generate up to 1Million Btus/hour, or approximately 425 horsepower heat into the ground. Destruction efficiencies demonstrated for PCE at >99.8. Bro-SoilTherm-EBJ2014